Heading 1

Heading 2

Heading 3

Heading 4

Heading 5

Heading 6

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

Block quote

Ordered list

- Item 1

- Item 2

- Item 3

Unordered list

- Item A

- Item B

- Item C

Bold text

Emphasis

Superscript

Subscript

About This Simulation

Learn how to optimize alcohol production in a fermentor. Will you be able to create the ideal conditions for the yeast Saccharomyces cerevisiae to produce bioethanol?

Learning Objectives

- Simulate yeast batch fermentation

- Outline the principles of fermentation and its applications

- Summarize the principal components of a fermentor and their function

- Experiment with the effect of temperature, pH, gas, and agitation on fermentation

- Analyze growth curves qualitatively to identify optimal growth parameters

About This Simulation

Lab Techniques

- Aseptic Technique

- Bioreactor or fermentor

Related Standards

- No direct alignment

- No direct alignment

- B.1 Microbiology: organisms in industry

Learn More About This Simulation

This simulation has been adapted from the original, longer “Fermentation” simulation.

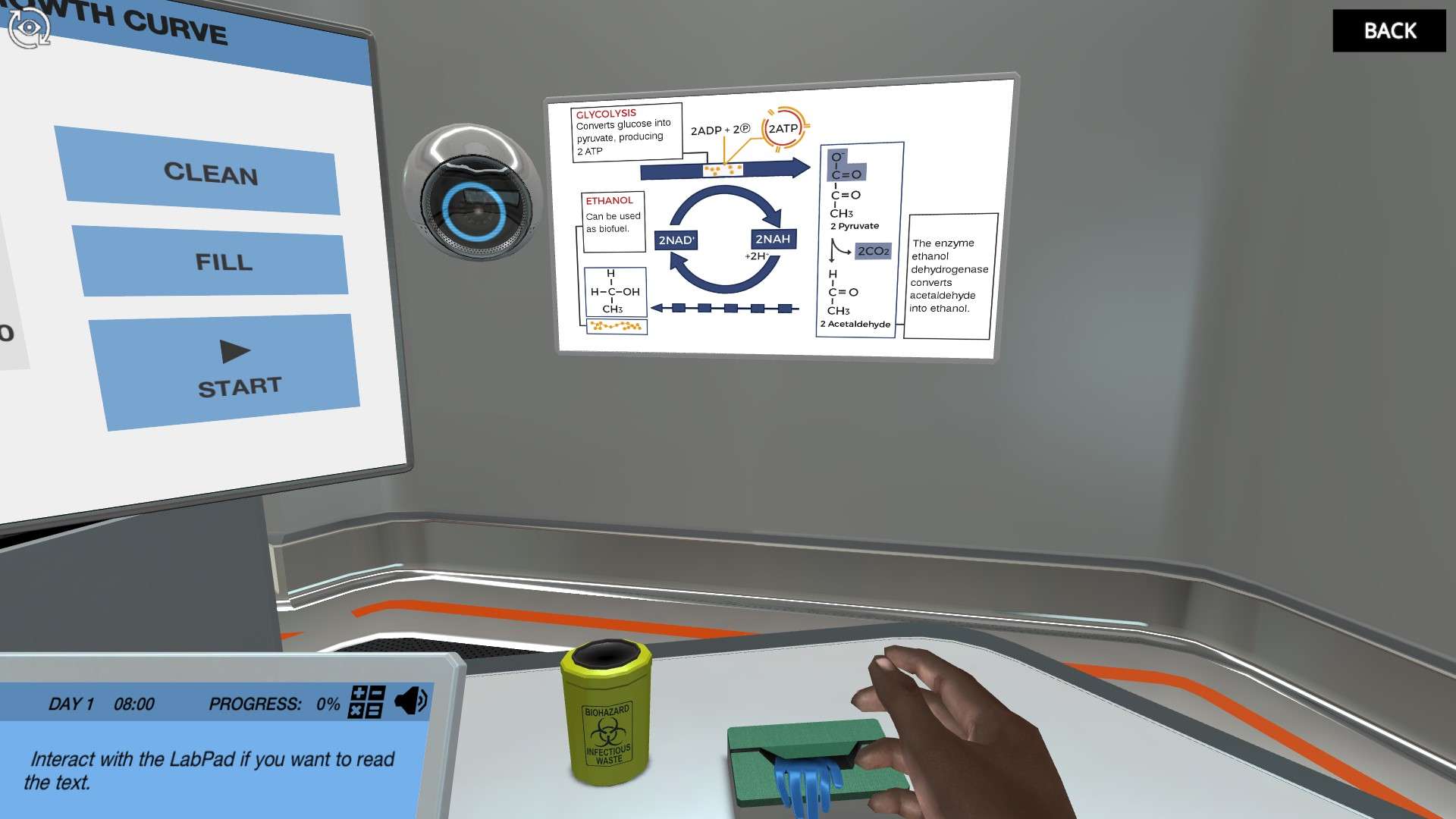

You will experiment with the growth conditions of the yeast Saccharomyces cerevisiae in order to produce as much bio-ethanol as quickly as possible. The production of ethanol through fermentation by the yeast is widely used to produce alcoholic drinks such as beer and wine. It can also be harnessed to sustainably produce bio-ethanol that could be used as fuel.

Setting up your experiment

Your mission will be to optimize bio-ethanol production on a pilot scale. After setting up the bench-top fermentor or bioreactor, you will add a yeast inoculum and run a fermentation experiment. Dr. One will guide you through the first experiment, including how to work aseptically and the first set of culture conditions. Once you are familiar with the equipment you can experiment freely with the fermentor.

Pilot scale fermentation

Because you are working in the virtual lab, you will be able to gather data very quickly. This allows you to test many different growth parameters and see the effects of different combinations of temperature, gas composition, level of stirring, and pH in a matter of minutes.

Qualitative data analysis

Once you have performed a number of fermentation experiments, you will compare the results. Dr. One will guide you through qualitative analysis of key parameters of the fermentation process. Can you decide together which culture conditions should be used tor optimal bio-ethanol production on an industrial scale.

RELATED SIMULATIONS

Fermentation

Aseptic Technique

For Science Programs Providing a Learning Advantage

Boost STEM Pass Rates

Boost Learning with Fun

75% of students show high engagement and improved grades with Labster

Discover Simulations That Match Your Syllabus

Easily bolster your learning objectives with relevant, interactive content

Place Students in the Shoes of Real Scientists

Practice a lab procedure or visualize theory through narrative-driven scenarios

FAQs

Find answers to frequently asked questions.

Heading 1

Heading 2

Heading 3

Heading 4

Heading 5

Heading 6

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

Block quote

Ordered list

- Item 1

- Item 2

- Item 3

Unordered list

- Item A

- Item B

- Item C

Bold text

Emphasis

Superscript

Subscript

A Labster virtual lab is an interactive, multimedia assignment that students access right from their computers. Many Labster virtual labs prepare students for success in college by introducing foundational knowledge using multimedia visualizations that make it easier to understand complex concepts. Other Labster virtual labs prepare learners for careers in STEM labs by giving them realistic practice on lab techniques and procedures.

Labster’s virtual lab simulations are created by scientists and designed to maximize engagement and interactivity. Unlike watching a video or reading a textbook, Labster virtual labs are interactive. To make progress, students must think critically and solve a real-world problem. We believe that learning by doing makes STEM stick.

Yes, Labster is compatible with all major LMS (Learning Management Systems) including Blackboard, Canvas, D2L, Moodle, and many others. Students can access Labster like any other assignment. If your institution does not choose an LMS integration, students will log into Labster’s Course Manager once they have an account created. Your institution will decide which is the best access method.

Labster is available for purchase by instructors, faculty, and administrators at education institutions. Purchasing our starter package, Labster Explorer, can be done using a credit card if you are located in the USA, Canada, or Mexico. If you are outside of North America or are choosing a higher plan, please speak with a Labster sales representative. Compare plans.

Labster supports a wide range of STEM courses at the high school, college, and university level across fields in biology, chemistry, physics, and health sciences. You can identify topics for your courses by searching our Content Catalog.

.png?fm=jpg&w=450&h=400)